Taizhou Huangyan Jiantai Mould Co., Ltd., is a professional enterprise engaged in the design and manufacture of automobile moulds.

Taizhou Huangyan Jiantai Mould Co., Ltd. is located in Huangyan, Taizhou, Zhejiang, the hometown of moulds in China. At the beginning of the company's establishment, the main development direction was the processing and manufacturing of precision medium and automobile bumper molds, large car lamp molds and automobile plastic interior and exterior trim parts molds. The company is formed by a group of industry elites with dreams and experience. The core team members all have more than 10 years of professional work experience, and the front-line operators have more than 5 years of work experience.

After years of walking, it has won the care and trust of the vast number of excellent customers with quality and integrity. The company has grown in size, and its technical and management levels have been continuously improved. The company has 110 employees. Among them, 40% are senior and intermediate technicians. With the efforts of all employees of the company, we won the ISO9001 quality management system certification in 2011, and became the director unit of Zhejiang Mould Association in 2014. At present, our company has a number of domestic advanced machining centers, EDM, CNC, and a large number of technical backbones have laid a good foundation for the rapid development of the enterprise.

Our company adopts CAD/CAM/CAE operating system in mold development and manufacturing, and establishes internal and external network system to realize product virtualization and development. In order to ensure product quality, the company takes "QUALITY FIRST" (product quality) as the principle and strictly follows the IS09001 quality management standard for management, which provides a strong guarantee for the company's product design, quality and production technology.

Faced with more intense market competition, Gentex seizes opportunities, effectively integrates resources, increases investment, and achieves resource sharing, complementary advantages and steady improvement with the companies it cooperates with, enabling us to The company shows vigor and high spirits. Adhering to the policy of "Precision Manufacturing, Honest Service, Continuous Improvement, and Customer Satisfaction", we will actively develop and keep pace with the times, making Jiantai a competitive and trustworthy enterprise. The company's main customers include: Great Wall, Chery, Changan, GM-Wuling and other vehicle companies.

Most mold engineers have more than 10 years experience, we regularly exchange mold manufacturing experience, have successful project experience in 2D and 3D molds in Europe, North America and Australia, provide manufacturing analysis reports, mold flow Simulation (includes mold cost by default)

View Mold Products

R&D personnel are the source of innovation. Under the leadership of the strong R&D team of Jiantai Mould, the scientific research projects have yielded fruitful results.

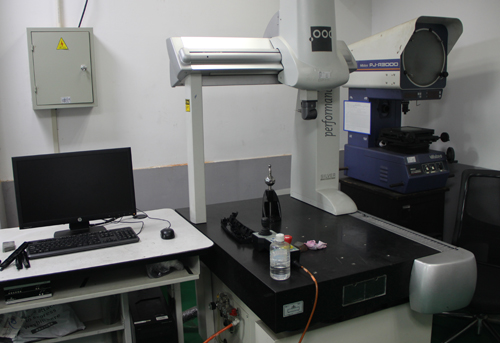

Gentech's quality team covers incoming inspection, process inspection, product inspection, electrode inspection, outgoing inspection and quality management system, with the support of various precision measuring equipment resources and quality personnel with relevant qualifications

High-demand and responsible QC department, experienced and English-speaking project department, with perfect Mould knowledge, careful design department, high service awareness, foreign trade department familiar with all kinds of moulds, old A series of supporting teams such as qualifications, high-efficiency mold processing department, etc., perform their own duties to ensure that all The project went perfectly.